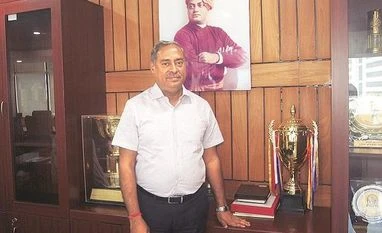

Coal India, world’s largest coal producer, has been facing criticism for not being able to cater to domestic demand and its one-billion tonne target seems a distant future. Anil Kumar Jha, who took over as company’s chairman and managing director four months ago, in a conversation with Avishek Rakshit, expressed confidence in increasing coal availability from as soon as November. Edited excerpts:

Coal India’s production hasn’t been enough to meet the power sector demand. What are doing about this situation?

We have kept an aspiration target of 652 million tonnes (mt) for this year, whereas our target according to agreements is less. Our capacity may not be that much, but since there is a requirement in the country, Coal India is going to rise up to the occasion and try to produce its best. During the monsoon, things were not that good and for the past 15 days, rains have been very heavy. So, our performance wasn’t up to the mark. But, from September 19, it has improved and we are going to touch 2 mt of daily production from the existing 1.4-1.5 mt by middle of October. To keep pace with the additional requirement from the power sector, expected at 6 per cent, and the demand from other sectors as well, we are going to grow by more than 12 per cent this year.

How do you see it improving in the coming months?

During the recent past, power generation has increased by leaps and bounds and to keep pace with, Coal India also increased production. But being in the infrastructure sector, things cannot be improved in a day – though we are tightening our belt and I’m sure that from November onwards, we would be able to provide the required coal to the power sector, if possible slightly more so that they can make up for their stock also.

In the case of National Thermal Power Corporation (NTPC), we are supplying 95-96 per cent of their requirement and the rest will be met in the coming months.

Evacuation of coal is a key challenge impacting production. How do you plan to address it?

We have gone for three major projects, which will increase our evacuation capacity by 100 mt. The first one is the 53-km-long Jharsuguda-Sardega railway line constructed at a cost of Rs 11 billion by Coal India and operations have started. The second one is the Tori-Shivpur line in Jharkhand, where the maximum job has been done and loading has started. The third is the East Corridor and East-West Corridor in Chhattisgarh where despatch can be started in a year or so.

Coal India has been considering owning own rakes. What is the update?

Discussion with the railway ministry for procurement tenders is at an advanced stage. We will procure but Railways will operate the rakes, and we will get a part of that revenue. Coal India board has already approved the proposal.

Do you think these railway lines and rakes can solve the issue?

There are a few places where evacuation will still be a problem and so we have devised a solution. For example, in Odisha’s Sundergarh district, the area is going to produce 80-85 mt. Even with our best possible efforts, it will not be possible to evacuate more than 65-70 mt. So, we will be using this un-evacuated coal to feed two 2X800 Mw (total 16,000 Mw) super-critical thermal pithead plants which will come up here. The land has been acquired, the state government has provided for the water and now, talks are on with NTPC to rope them in. NTPC will also help us get PPAs. Central Coalfields is also trying to identify a few places where such type of plant, where evacuation is a problem, can be put up.

You are opting for mechanisation of mines, but your production methodology is labour intensive. Do you anticipate any industrial unrest?

If we go for mechanisation in a large scale, there will not be a single job loss; we will train and retrain the workers and put them where they can be gainfully utilised. In case of transfers, we ask for their consent and those who don’t, we try to accommodate them in nearby mines or locally but if the situation so demands, we will think otherwise also. We have large mines producing 30-45 mt, which have a very high standard of mechanisation. But yes, we are still labour intensive and we will try to see how gradually these labours can be transferred from a place of high risk to a place of low risk.

You have been extensively focusing on opencast mining and underground mines are getting closed. Why is it so?

In India, mining started with underground only. But everything now depends on the economy, and in underground mining, the scale of operations cannot be that high. It is extremely hard to produce even 10 mt from an underground mine as compared to opencast. I personally feel that till the economy sustains, we should go for opencast mines and there should be a judicious mix of both so that when the time comes, we can switch to underground mines. At present, the rate of production, our opencast reserves can last more than 100 years.

Unlock 30+ premium stories daily hand-picked by our editors, across devices on browser and app.

Pick your 5 favourite companies, get a daily email with all news updates on them.

Full access to our intuitive epaper - clip, save, share articles from any device; newspaper archives from 2006.

Preferential invites to Business Standard events.

Curated newsletters on markets, personal finance, policy & politics, start-ups, technology, and more.

)