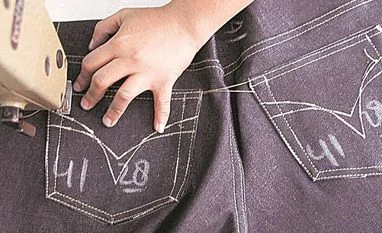

After more than doubling in a few months and showing no signs of corrections, high cotton prices have compelled denim makers to reconsider their product mix in favour of blended jeans. This means less conventional jeans that are made of almost 100 per cent cotton and indigo dye.

Surging cotton prices, coupled with other raw materials, have shot up input costs by 30 per cent. Raw cotton prices have more than doubled from Rs 35,000 per candy of 356 kg in mid-2020 to over Rs 75,000 now. With the denim industry consuming at least 10 per cent of India’s cotton, the rise in prices has impacted all kinds of players.

However, while denim makers have been able to pass on much of the cost hike to buyers leading to better realisations in the export market, in the domestic market the industry — including fabric makers, distributors and retailers — has largely absorbed it.

“Over the last 12 months or so, the industry has already seen anywhere between 25 and 40 per cent price hike due to multiple factors including global supply chain disruptions and cotton price hike. End consumers at the domestic retail level have taken a 10-15 per cent price hit in denim garments, which is not commensurate with market reality. However, if cotton price continues to remain at current levels, there might be another round of hike in the next 3-6 months,” said Gaurav Davda, head, corporate finance & strategic initiatives, Jindal Worldwide Ltd., a leading denim maker with over 140 million metres per annum capacity.

In the current scenario, denim makers are looking at ways to mitigate the input cost rise in the domestic market. Cotton forms nearly 70 per cent of the raw material costs. One solution is to enhance the share of blends in the overall product mix.

“Denim makers are now looking at substitutes for cotton yarn and the most possible way to do that is through blended products. This way, the industry can ensure that least impact is passed on to retail consumers,” said Vinay Thadani, chief financial officer of Vishal Fabrics Ltd.

According to Thadani, currently anywhere between six and 10 per cent of the product mix is blended products where raw materials such as viscose and Lycra are used.

“But now, the share of blended products in the product mix could go up to 25-30 per cent, as manufacturers are avoiding fully cotton-based products due to high prices,” Thadani added.

Experts believe while blended products haven’t been so popular among retail consumers, the unprecedented rise in cotton prices has forced denim makers to look at it as an alternative.

“Denim makers are being forced to manufacture more blended products since these are unprecedented times with hitherto unknown levels of cotton prices. The other way to mitigate the impact, at least in the domestic market, is by looking at other types of cotton that are of lower price range and coarse count that could be used as blends,” said P R Roy of Diagonal Consulting, a leading textile consulting firm.

The export markets, on the other hand, have been more favourable with the industry being able to pass on the impact to a large extent.

According to Davda, larger players like Jindal Worldwide have had lesser impact due to a wide range of products in different price ranges offered to international and domestic buyers, which allows transfer of input cost hike to certain categories.

“We offer denim fabrics anywhere between Rs 100 and over Rs 300 per metre. Denim makers, who do not have a large capacity and are unable to cater to all price points, are finding it exceedingly difficult to pass on the cost to buyers. This is because they are able to offer only products in the Rs 100 per metre range, where even a Rs 5 per metre price hike seems huge for buyers,” he added.

Industry estimates peg the denim manufacturing capacity in India at roughly 1.5-1.6 billion metres per annum (bmpa), half of which is organised and led by a few large listed players such as Arvind Limited, Jindal Worldwide, Nandan Denim and Vishal Fabrics. Overall, large players alone control roughly 25-30 per cent of the organised denim manufacturing capacity in the country.

Meanwhile, Vishal Fabrics has announced that the company has added a new denim line that started operations at the end of last month with a total capacity of 10 million metres per annum (mmpa), even as it plans a second line of another 10 mmpa capacity. With the two additional lines, its annual capacity will increase to 100 mmpa at its Dholi unit in Gujarat.

Unlock 30+ premium stories daily hand-picked by our editors, across devices on browser and app.

Pick your 5 favourite companies, get a daily email with all news updates on them.

Full access to our intuitive epaper - clip, save, share articles from any device; newspaper archives from 2006.

Preferential invites to Business Standard events.

Curated newsletters on markets, personal finance, policy & politics, start-ups, technology, and more.

)