Problems in the power sector, which was a sunrise industry even during the 2008 economic slowdown, seem to be spilling over to suppliers of equipment. And, unlike five years back, there are many players supplying a range of products from boilers and turbines to nuts and bolts, and what industry calls "balance of plant". Enthused by the prospects, L&T had joined hands with Mitsubishi of Japan to produce environment-friendly super-critical equipment in 2007. A little later, Bharat Forge had got into collaboration with Alstom to start Alstom Bharat Forge. Thanks to the various problems faced by the power producers, the capacity of all the equipment makers is underutilised. "This order alone is not enough," says Shailendra N Roy, director, L&T. Though the utilisation of L&T's JV production facility in Gujarat will increase to 75 per cent from 62 per cent, it needs to be more. "For a year-and-a-half, we have not received orders. We need to bag another order of this size (Rs 5,680 crore) to break even."

The L&T JV is banking on an NTPC order. Besides, as many as eight state utilities are expected to announce their orders in the current financial year. It has already bid for three of these orders. For BGR, the NTPC order for turbines had been under discussion since May 2011. It was a Rs 1,600-crore order for two units of 660 Mw each. The turbine order was placed on BGR which has a 74/26 venture with Hitachi. "BGR had given six extensions and held the price for more than 18 months. In the absence of a timeline for the award of contract, it was not possible for BGR to extend the validity of the contract," says a company spokesperson.

The BGR and Siemens cases may not be exceptions but an industry observer says it should not be a cause of worry since even if half the orders placed on a company go through, new players will be able to survive. However, a researcher with Emkay Global says that the default in payments and orders not materialising may not be rampant. "It will depend on the financial health of the state utility. Besides, when there is a demand for power in the country, it is bound to flow down to companies as orders," says the researcher who does not want to be named.

Almost 100 gigawatt (or 100,000 Mw) of orders were finalised between 2010 and 2012 with annual ordering peaking at 56 gigawatt in 2010-11. This had the impact of breaking BHEL's hold over the market for boilers, turbines and generators. It was simply beyond the capacity of one company to execute all these orders. "BHEL's market share reduced from 95 per cent in the five-year period ending 2007 to 40 per cent in the 11th Five-year Plan ended March 2012. Expect its market share to decline further to 28 per cent," says an Emkay report. Currently, orders for 126.8 gigawatts coal-based power plants are already placed with domestic as well as international equipment manufacturers.

For BHEL, both competition and the slowdown in the market are creating problems. The company announced on Monday that its net profit for the last financial year, 2012-13, dipped 8 per cent, declining for the first time in more than a decade. The largest power equipment manufacturer in the country posted net profit of Rs 6,485 crore in 2012-13 as compared to Rs 7,040 crore in the previous financial year. Turnover increased by a marginal 1 per cent to Rs 50,015 crore from Rs 49,510 crore in 2011-12. "We had a turnover target of Rs 100,000 crore for the 12th (Five-Year) Plan. Now, we are taking a re-look at it," B P Rao, BHEL Chairman and Managing Director, said at the company's annual press conference.

| A few big orders |

* L&T bags 1320 Mw order from Rajasthan Vidyut Utpadan Nigam

* Alstom Bharat Forge books NTPC's Nabinagar order in Feb 2013

* BGR Energy books NTPC's 1600 Mw order for its Lara plant in Dec 2012

* BGR Energy bags 1200 Mw order from Damodar Valley Corporation in Sep 2012

* Toshiba JSW bags 2400 Mw order from NTPC's Kudgi plant in Feb 2012

More From This Section

The problems

* Cheaper Chinese power equipment preferred by private power producers

* The new power capacity is now under-utilised

* Under-utilisation can be as high as 50 per cent in some cases

* Many power projects are stalled owing to lack of coal supply

* Private power companies froze expansion plans; reducing ordering

For the industry, overcapacity came along with payment delays and cancellation of orders. M S Unnikrishnan, managing director and CEO of Thermax, sees no expansion in the sector until the current capacity is completely utilised. But, he adds, there is potential to double the size of the industry in India and even export. "Some early entrants like JSW Toshiba gained from bulk orders. We (Thermax) expect further bulk orders by the government which can help the capacity that is lying idle," says Unnikrishnan. He fears idle capacity would lead to job cuts in the sector. Already, companies in supply chain and balance of plant, and in components, are known to be laying off people, especially in the Trichy belt. Thermax has set up a greenfield plant in Shirwal near Pune to manufacture super-critical boilers. This is in 52:49 joint venture with American company Babcock & Wilcox. The joint venture can manufacture super-critical boilers with a configuration of over 600 MW, as well as sub-critical boilers over 300 MW.

Bulking up

The bulk order mechanism was devised in the 11th Five-year Plan when it was realised that uncertainty of orders and consequent delays in execution by BHEL had derailed targets in the preceding five years. The first bulk tender covered some 11 units of 660 Mw for Mouda, Solapur, Meja, Nabinagar and Raghunathpur power plants of NTPC and Damodar Valley Corporation. The second one covered four 800 Mw units at Kudgi, Lara, Darlipali and Gajmara. Besides, Darlipali, NTPC faced problem even at Gajmara in Orissa. This project has now been shifted to Gadarwara in Madhya Pradesh.

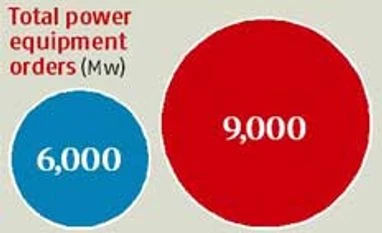

With fuel shortages and clearances relating to land and environment making things difficult for power projects of not just NTPC but even private generators like Reliance Power and GVK, the market for equipment suppliers looks bleak but the Emkay paper expects annual orders of 6.5 gigawatt over the next five years, assuming a commissioning cycle of four years for a power plant and a demand of 39 gigawatt. Even if this becomes a reality, the industry looks all set for a churning that may see realignment of joint ventures and buy-outs of capacity that have already been built.

)