The 9.02-km Atal Tunnel inaugurated by Prime Minister Narendra Modi on Saturday is not just the longest facility at such an altitude but is also a technology marvel in many ways. Global technology giant Siemens has provided technology for automation of the tunnel across various processes including lighting.

Sunil Mathur, Managing Director and CEO, Siemens Limited, told Business Standard that the tunnel has a fault-tolerant automation system that minimises the probability of a production failure to nearly nil, playing a decisive role when it comes to achieving maximum productivity.

“The Atal Tunnel will be a benchmark as it is the longest tunnel at this altitude,” Mathur said. The company’s global expertise and local competence and technical-knowhow make it a partner for all stakeholders-–manufacturers, designers, system integrators, and operators, is its biggest differentiator, he said.

The Siemens technology will provide electrification, automation and digitalisation solutions for local and remote monitoring, connectivity, lighting, ventilation, power distribution and fire safety systems.

The tunnel is at an elevation of 3,100 metres (10,000 feet). The Lahaul valley was earlier cut off for about six months every year due to heavy snowfall.

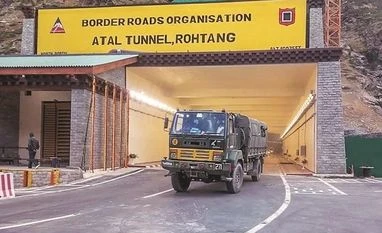

The south portal (SP) of Atal Tunnel is located at a distance of 25 km from Manali at an altitude of 3,060 metres, while the north portal (NP) of the tunnel is located near village Teling, Sissu, in the Valley at an altitude of 3,071 metres.

It is a horse-shoe shaped, single-tube, double-lane tunnel with a roadway of eight metres and an overhead clearance of 5.525 metres.

The tunnel, built by the Border Roads Organisation (BRO) at a cost of about Rs 3,300 crore, is extremely significant from the point of view of the country's defence.

The company feels that overcoming the challenge of design and engineering is key to any project.

“Every tunnel project is a challenge in terms of both design and engineering. Many different disciplines and departments have to be coordinated, and the design process must be cost-optimised. This is where Siemens’ Automation and Digitalisation offers many benefits including optimizing the design, engineering, commissioning, operation, service, safety and modernization,” he said.

SAIL supplied steel for the construction of the tunnel, which will be conducive to all-weather traffic, connecting Manali to Lahaul and Spiti Valley in Himachal Pradesh throughout the year.

On the company’s expansion plans in India, Mathur said, “Siemens’ business structure is well-oriented toward meeting the needs of the Industry. We are firmly committed towards partnering and contributing to the sustainable growth of the country.”

The Atal Bihari Vajpayee government had taken the decision to construct the strategic tunnel below the Rohtang Pass on June 3, 2000, and the foundation stone for the access road to the south portal of the tunnel was laid on May 26, 2002.

The Modi government had decided to name the Rohtang Tunnel as Atal Tunnel in December 2019 to honour the former prime minister who had passed away the previous year.

What the technology does - As the Rohtang tunnel will have heavy traffic, vehicular management and checking pollution and injecting fresh air inside is a priority

- Fire detection and fire suppression systems from Siemens offer protection to the 8 control rooms inside the tunnel.

- Continuous monitoring of the health status of the fire detection will help protect the assets and ensure there is no downtime/closure of the tunnel

- The technology also optimises processes for predictive maintenance and enables cost savings due to energy transparency and greater switchboard availability. Switchboards powering the ventilation system at this height face tough climatic conditions like temperatures of -15 degrees to +20 degrees

- Ensures reliable operation specially in Tunnels and avoids downtimes

- Integrated with Automatic Synchronization which leads to replacement of defective components during plant operation, configuration changes and maintains high level communication

Unlock 30+ premium stories daily hand-picked by our editors, across devices on browser and app.

Pick your favourite companies, get a daily email with all news updates on them.

Full access to our intuitive epaper - clip, save, share articles from any device; newspaper archives from 2006.

Preferential invites to Business Standard events.

Curated newsletters on markets, personal finance, policy & politics, start-ups, technology, and more.

)