Electronics and Information Technology (IT) Minister Ashwini Vaishnav announced on Tuesday that the first semiconductor fabrication (fab) chip is slated for announcement in a few weeks, and India is poised for a thriving and expanding chip industry and manufacturing ecosystem in the following three to four years.

According to a report released by Deloitte, the Indian semiconductor business would generate $55 billion in revenue by 2026. A senior state government official had told the media on February 20, 2023, that the Vedanta-Foxconn JV had decided on the Dholera Special Investment Area near Gujarat as the site for their semiconductor and display production facility.

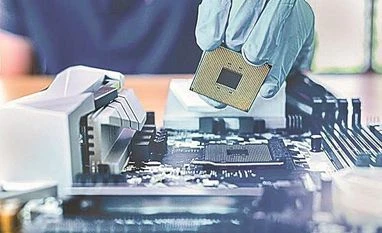

What exactly is a semiconductor chip, what goes into its making and how does India assemble each component vital for its production?

All contemporary electronic devices and technologies use semiconductors or chipsets in a variety of applications, from electronic goods and IT hardware to defence technology, industrial electronics, medical electronics, and automation, among others.

A semiconductor chip is an electric circuit containing several components such as transistors and wires constructed on a semiconductor wafer. An "integrated circuit (IC)" is an electronic device made up of many of these parts. During the production process, a computer patterns the component arrangement on a photomask (reticle) before projecting it onto a semiconductor wafer.

Here’s a breakdown of the key materials required in the production of a semiconductor chip:

Silicon - Silicon is the most important component required for manufacturing a semiconductor chip. India, the second-largest importer of silicon metal worldwide, purchases the majority of its silicon metal from China, the United States, and the United Kingdom according to data updated through 2022 by Volza India. The top 3 countries importing silicon metal are the United States (32,379 shipments), India (19,761 shipments), and Vietnam (7,129 shipments). The data further states that 738 Indian importers took in 19.8K shipments of silicon metal from 901 Suppliers.

In 2022, an estimated 59,000 metric tonnes of silicon were produced in India and 8.8 million metric tonnes of silicon were expected to be produced globally. As a result, significant amounts of silicon are imported to meet the semiconductor production demand.

Germanium - India obtains the majority of its germanium supplies from countries like the United States, the United Kingdom, and Germany. India is low on germanium output and relies heavily on import. China produced the most germanium in the world in 2021, with a refinery output of this metal estimated at 95 metric tonnes.

Germanium was crucial in the creation of the first transistor, which led to the discovery of its value as a semiconductor. Because silicon has a wider bandgap and stable silicon oxides are available, interest in employing silicon rather than germanium increased in the late 1950s.

Gallium Arsenide - Gallium is a metal mostly utilised in production of electronic devices. India has a large supply of bauxite ores, which include traces of gallium but are not the primary source of the metal. According to the Indian Minerals Yearbook 2020, despite the fact that India has an abundance of bauxite ores, no production has been documented lately due to the difficulty of commercially generating gallium.

To make semiconductors for the electronic industry, gallium-based materials like gallium arsenide (GaAs) and gallium nitride (GaN) are employed. According to Volza's India import data, India is a major importer of metal and receives the majority of its gallium from France.

India lags behind more competitive bases like China and Vietnam in the creation of semiconductor wafer fabrication (FAB) units because of a fragile environment and a lack of resources. So the government aims to focus on fostering the semiconductor industry so that India can become a lead supplier of semiconductors in the next five to six years. Even though India doesn't produce semiconductors, India is one of the top nations for semiconductor design talent, accounting for up to 20% of all semiconductor design engineers worldwide.

The Indian government has made domestic semiconductor production a top priority in response to the severe implications of chip scarcity, including the disruption of the supply of gadgets and autos, particularly after the Covid-19 pandemic.

Unlock 30+ premium stories daily hand-picked by our editors, across devices on browser and app.

Pick your favourite companies, get a daily email with all news updates on them.

Full access to our intuitive epaper - clip, save, share articles from any device; newspaper archives from 2006.

Preferential invites to Business Standard events.

Curated newsletters on markets, personal finance, policy & politics, start-ups, technology, and more.

)