Steel Minister Chaudhary Birender Singh today urged the extractive industry to ensure that ecological balance is maintained in operations and disposal of waste materials.

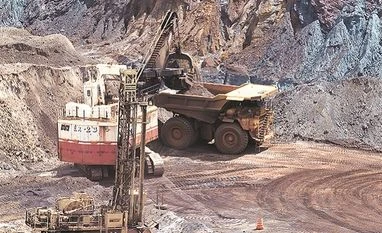

Mega investments in extractive industries like oil and gas and mining have the potential to be a spring board for overall development, the minister said.

However, at times, issues "like ... Impact on the surrounding communities, pollution and environmental catastrophe are associated with the industry," Singh said at the National Extractive Industry and Sustainable Development Summit here.

For sustainability of the industry and nature, it is the duty of the government and also of organisations in this sector to apprehend this kind of imbalance, he said, adding steel companies have been asked to optimise the use of resources so that there is minimum wastage or zero wastage.

Singh said that for sustainable development, the government is exploring the possibility of scrap-based steel plants to utilise waste for steel making and reduce burden new resources.

Steps are also being taken to ensure that the steel industry needs minimum carbon footprint. Rashtriya Ispat Nigam Ltd (RINL), under the Ministry of Steel, has recently set up a power plant that utilises waste gases generated in the plant.

The minister said he is also examining if methanol can be made using waste gases generated in steel plants. Recently at some of the mines where mining were to take place the problem was gas.

Methanol can be produced from natural gas, coal and renewable sources such as municipal waste, biomass and recycled carbon dioxide.

The steel ministry is also focusing on enhancing capacity utilisation and technology upgradation as these can help in proper utilisation of our extractive minerals.

Under the National Steel Policy, more coal washeries will be set up to reduce the dependence on foreign countries for availability of coking coal.

"We import 80 per cent of coking coal from other countries like Australia and prices fluctuate between 70-300 dollars which is very disturbing for us," he said adding the addition of washeries can reduce imports by one-third.

Mega investments in extractive industries like oil and gas and mining have the potential to be a spring board for overall development, the minister said.

However, at times, issues "like ... Impact on the surrounding communities, pollution and environmental catastrophe are associated with the industry," Singh said at the National Extractive Industry and Sustainable Development Summit here.

More From This Section

The challenge is to achieve a balance to effectively leverage these resources for economic and social development and at the same time prevent the negative impact on environment, the minister said. Playing with nature can be harmful, he warned.

For sustainability of the industry and nature, it is the duty of the government and also of organisations in this sector to apprehend this kind of imbalance, he said, adding steel companies have been asked to optimise the use of resources so that there is minimum wastage or zero wastage.

Singh said that for sustainable development, the government is exploring the possibility of scrap-based steel plants to utilise waste for steel making and reduce burden new resources.

Steps are also being taken to ensure that the steel industry needs minimum carbon footprint. Rashtriya Ispat Nigam Ltd (RINL), under the Ministry of Steel, has recently set up a power plant that utilises waste gases generated in the plant.

The minister said he is also examining if methanol can be made using waste gases generated in steel plants. Recently at some of the mines where mining were to take place the problem was gas.

Methanol can be produced from natural gas, coal and renewable sources such as municipal waste, biomass and recycled carbon dioxide.

The steel ministry is also focusing on enhancing capacity utilisation and technology upgradation as these can help in proper utilisation of our extractive minerals.

Under the National Steel Policy, more coal washeries will be set up to reduce the dependence on foreign countries for availability of coking coal.

"We import 80 per cent of coking coal from other countries like Australia and prices fluctuate between 70-300 dollars which is very disturbing for us," he said adding the addition of washeries can reduce imports by one-third.

)