Symbiosis has existed in human history for thousands of years and percolated into almost every aspect of livelihood, industry, governance and geopolitics. It sees robust application in today’s world working towards greater sustainability through inclusion, preservation and interaction.

A mature symbiotic relationship between the government and the industry is best demonstrated when either or both enter a phase of uncertainty, anxiety and unexpected national calamity, like the Covid-19 pandemic.

In this phase of a gradual and cautious “unlock” to resume economic activities, the Indian automobile industry has been one of the quickest to restart operations from early May in the green and orange zones. We are going through our share of hiccups with a broken supply chain, a depleted work force and a depressed consumer sentiment.

The industry has been engaged in a dialogue with the Union government on a specific set of fiscal measures that would be required to revive demand. These include reduction in GST rates from 28 to 18 per cent for all vehicle categories and components; the introduction of an incentive-based scrappage policy, with monetary incentives in the form of rebates in GST, road tax and registration charges. We have also requested for a major programme to be launched for diesel/CNG bus procurement by the state transport undertakings.

While we continue to be hopeful for such a fiscal package to be announced by the government, in this article I would like to point out this trend all over the world, of respective governments providing direct fiscal support to the automobile sector in view of their importance in the overall economy of the those countries.

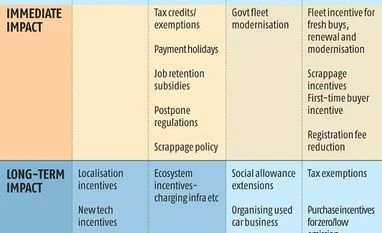

The support provided by the governments, from Germany to Thailand, typically is a mix of support to benefit both the manufacturer and the consumer. There are immediate stimulus supports like tax exemptions, payment holidays, first-time buyer incentives to fleet renewal and scrappage incentives. There are structural support measures like localisation, new technology and employment incentives for automakers as well as government fleet modernisation and subsidies for ride-hailing services.

Apart from a temporary reduction of VAT, in Germany’s Euro 50-bn package for the economy, there are specific support mechanisms for the industry — from extending tax exemptions for battery electric vehicles till 2030, to support in new technology investments, to incentives for electric mobility infrastructure and incentives for bus and truck fleet modernisation.

In Russia, 12 automakers are part of the 246 “system-forming” enterprises to get access to tax credits. There is also a subsidised loan for first-time buyers and concessional leasing for ride-hailing companies. State enterprises have been asked to replace old vehicles and modernise fleets a year in advance.

As part of the Euro 45-bn recovery package, French automakers are looking forward to specific support mechanisms like sales incentives for EVs, a scrappage scheme and incentives for setting up charging infrastructure.

In China, the enforcement of emission standards for LCVs has been pushed back by a year, while the new energy vehicle purchase subsidies have been extended till 2022. A “reward replacement” programme has been set in place to scrap one million old diesel trucks.

Even in countries like Malaysia and Vietnam, governments have announced exemption of sales tax or vehicle registration fees, which are quite substantial. In fact, the various forms of support have been summarised in the grid accompanying this article.

Such direct interventions by the government ensure that the industry takes minimum time to revive.

The Indian automobile industry contributes about 7 per cent of India’s GDP and accounts for nearly 49 per cent of the manufacturing GDP. Further, it provides about 37 million jobs, directly and indirectly, across the value chain. Importantly, the auto industry accounts for about 15 per cent of India’s GST collections and in FY19, its contribution was about Rs 1,50,000 crore to the exchequer. In addition, the auto industry exports goods worth $27 billion, which is 8 per cent of the merchandise exports, to more than 190 nations globally.

The directly employed workforce is one of the most skilled, matching global standards in capability and workmanship. The combined automobile network of close to 25,000 dealer showrooms and service centres covers more than 2,000 cities and towns, becoming a source of quality employment for the educated and aspirational youth even in rural India. The central role that an automobile plays in everyday life, from delivering milk to your doorsteps to carrying supplies for our soldiers protecting our borders, cannot be denied.

Knowledge is also a crucial contribution of the industry to nation building, though not written about. We adopt and absorb new technologies, processes and standards from other industries like aerospace, defence, consumer durables and FMCG to constantly enhance internal benchmarks.

Concurrently, the automobile industry is a great source of knowledge on manufacturing, procurement, design, logistics, service, retail and customer relationship management. Every year we apply for several patents in various fields.

The Indian automobile industry’s goals are totally complementary with that of the government. The very nature of our business allows us to be both technology and human resource intensive at the same time.

The impact of our operations in every corner of the country, across socio-economic strata, makes us unique in our diversity as well as inclusiveness. But this scale and scope can be sustainable only when the government realises our relationship is truly symbiotic, beyond transactional. It is a two-way exchange of support, proaction and assurance to keep both the economy and the ecosystem robust.

In the last two decades the automotive industry has grown significantly in India to make its position in global landscape permanent. The value created by the industry can be visualised by its progress from manufacturing around 500,000 passenger vehicles in 1998-99 to more than four million in 2018-19. We have increased our production of commercial vehicles from around 135,000 to more than 1,100,000 in 2018-19. In two-wheelers, we moved up from around three million to more than 24 million during this time. However, last year’s downturn along with the debilitating impact of Covid-19 are likely to set back the industry to volumes achieved a decade back unless pump-priming is done to reverse the situation like all other automotive manufacturing countries are doing globally.

The author is president, Society of Indian Automobile Manufacturers

Unlock 30+ premium stories daily hand-picked by our editors, across devices on browser and app.

Pick your 5 favourite companies, get a daily email with all news updates on them.

Full access to our intuitive epaper - clip, save, share articles from any device; newspaper archives from 2006.

Preferential invites to Business Standard events.

Curated newsletters on markets, personal finance, policy & politics, start-ups, technology, and more.

)