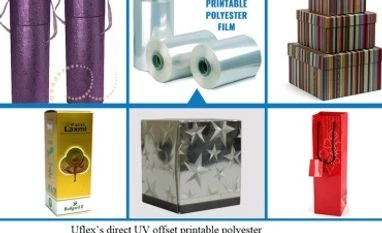

Flexible packaging major Uflex Ltd has launched direct UV offset printable polyester film, which allows direct surface printing without primer or corona treatment. This film helps in minimising the lead time at convertors’ end and enhances print results with high quality resolution of pictures.

UV offset printing on non-absorptive surfaces is getting popular by the days. It gives an ultimate packaging solution for board lamination and decorative printing. The daunting challenge in this segment, however, remains the availability of right kind of substrate where direct printing can be done without any primer/treatment.

Liquids do not wet surfaces with free energies lower than their surface tension. On the contrary an extremely high surface free energy as compared to the surface tension of the ink will also result in poor wetting and adhesion. Therefore according to printing industry experts, for best wetting and ink adhesion on to non-absorptive surfaces the ‘dyne level’ or the surface free energy of the substrate should be about 10 dynes above the surface tension of the ink.

Unfortunately many polymeric substrates have too low surface energy required for good printing and ink adhesion and therefore the substrate has to be remedially modified in order to make it printable.

This modification is usually done with an adjustable corona treatment or by applying a suitable primer coating. Corona treatment is fast and relatively inexpensive, but surface dyne levels are susceptible to loss or decay during prolonged storage and upon contact with some fountain solutions. Precautions must be taken to obtain a uniform dyne level that is not too high. Corona treatments can at times also dramatically increase troublesome static charges in the material treated. Therefore to avoid this, primer coatings that adhere to both the substrate and to the subsequently applied inks are used. This as one could well imagine is an elaborate and time consuming process that has been posing further challenges for the convertors.

To solve this challenge, Uflex Ltd has engineered a speciality polyester film, F-UVC film, which is suitable for direct UV offset printing without requiring any primer/treatment. The film is available in both bare transparent and metallised variants, where the un-metallised side is used for UV offset printing and UV curing.

Also Read

“Primer coating for rendering the films printable is a cumbersome and time consuming exercise at the convertors’ end. The coating machine is a big capital investment in itself. Therefore with this new innovation by Uflex, the convertors can heave a sigh of relief. Not only does the film increase operational efficiencies of convertors but also restricts their capital expenditure,” explained J K Sharma, AGM, technical service and new product development (films), Uflex Limited highlighting the benefits of the Direct UV Offset Printable PET Film

Ashok Chaturvedi, chairman and managing director, Uflex Limited, added, “Our feedback loop in the global market is very strong. We are always in touch with our clients globally and are promptly responsive to their needs. Convertors had been facing difficulties with primer coating of the films as it takes a lot of time. This had been impeding their productivity. I am happy that the team at Uflex addressed the pain point of convertors by engineering the UV offset printable PET film, which now permits surface printing without any treatment.”

)