Earlier this month, the Council of Scientific and Industrial Research (CSIR) launched a unique initiative with the health of the planet in mind. It encouraged its employees across India to forgo ironing on Mondays, and instead turn up in wrinkled clothes.

The campaign was rooted in the idea that if millions of Indians skipped ironing just once a week, a good deal of energy would be saved, and it would significantly reduce carbon emissions.

Across India’s corporate landscape, various companies are coming up with offbeat eco-friendly ideas.

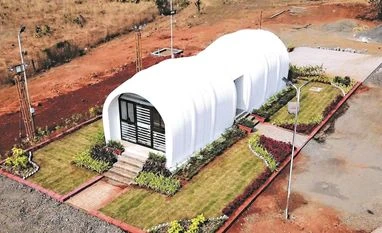

Recently, to build its office in Khalapur, Maharashtra, Godrej and Boyce decided to forgo traditional construction methods altogether. Instead, the Godrej group’s flagship company turned to 3D construction printing. The result was a small, 48-square-metre office, aptly named “The Cocoon”, built in 40 hours flat.

"Besides being efficient, 3D printing allows for complex, customised architectural features at comparatively lower costs," explains Tejashree Joshi, head of environment and sustainability at Godrej & Boyce.

The technology also enables the use of recycled material. “The recycled concrete aggregates used are from the construction and demolition debris recycled at the Godrej recycled concrete material plant, which is powered by 100 per cent renewable energy,” Joshi says.

This approach diverts waste from landfills and reduces reliance on virgin construction materials.

Signify, earlier called Philips Lighting, has also introduced 3D-printed luminaires made from 100 per cent recyclable polycarbonate material. The company invested 271 million euros – 88 per cent of its R&D expenses – in sustainable innovation globally in 2023.

In 2021, the firm launched an A-class 210 lumens per watt bulb with a lifespan of up to 50,000 hours. The firm also removed an average of 2,500 tonnes of plastic from its product packaging, equivalent to almost 125 million half-litre polyethylene terephthalate (PET) bottles. "Our packaging is also smaller, helping reduce 6,000 tonnes of CO2 emissions per year," says Nikhil Gupta, head of marketing, strategy, and government affairs at Signify.

Tech firm Zoho's campus in Guduvanchery, Chennai, meanwhile, incorporates green design elements with rainwater management systems. The 1.5-acre campus can store over 45 million litres of water, which helps replenish groundwater levels and mitigates the impact of natural calamities.

“During excessive rains, the infrastructure allows the water from the terraces and roads across the campus to be diverted to the underground storage tanks and then to the pond area,” says Praval Singh, vice president of marketing and customer experience at Zoho Corp.

When the ponds fill up, the overflow goes into the main storm-water drainage.

The campus also uses water from a well for household needs and for fire hydrants. Singh says the stored water can serve more than 12,000 Zoho employees on the campus for 3-4 days in case of emergencies.

During Cyclone Michaung, which struck Chennai in December last year, the rainwater management system helped prevent waterlogging inside the Guduvanchery campus.

British banking and insurance firm NatWest Group decided to make the climate fight personal when it launched the Giki Zero app in 2021. The app helps employees track and reduce their carbon footprint by helping them calculate their electricity, water and gas usage, explains Saurabh Gupta, head of finance and climate champion network sponsor at NatWest Group, India.

IT major Infosys, too, has implemented a range of sustainability measures over the past decade, including innovative cooling systems, 100 per cent food waste recycling, and ultra-low-flow taps to conserve water. "These steps were pioneering when implemented and set new benchmarks for sustainability," says Guruprakash Sastry, associate vice president and regional head-infrastructure at Infosys.

Hindustan Zinc, a subsidiary of Vedanta Ltd, which aims to drastically reduce its emissions, has set up a 60 million litres per day sewage treatment plant in Udaipur, Rajasthan, through public-private partnership. “This plant has so far reduced freshwater dependence by 36 per cent,” says Pradeep Singh, chief health, safety, environment and sustainability officer, Hindustan Zinc.

The company has also implemented zero liquid discharge plants at its smelters and mines, so that industrial wastewater is not pumped back into the environment. It also highlights its use of battery electric vehicles in underground mining at its Rajpura Dariba complex in Rajasthan and LNG vehicles for logistics, besides a dry tailing plant at Zawar Mines near Udaipur that has enabled the reuse of over 80 per cent of processed water.

The challenges

3D construction printing requires significant initial investment and skilled operators. "There's broader industry resistance to adopting new methods, which can slow down its integration into mainstream construction practices," says Tejashree Joshi, head of environment and sustainability, Godrej & Boyce.

Green initiatives, whether deploying renewable energy or implementing water stewardship projects, face challenges that “span from technological hurdles to policy incentives, regulatory compliance, and economic viability," notes Pradeep Singh, chief health, safety, environment and sustainability officer, Hindustan Zinc.

)