For Attero Electronics Asset Management Company, waste is valuable. Within a short period, the company has earned acclaim from the likes of the National Aeronautics and Space Administration in the US for its unique method of extracting gold, silver and nickel from electronic waste.

In 2008, an effort to sell or recycle a faulty laptop by brothers Rohan and Nitin Gupta led to an entry into the e-waste management business. When they failed to find a proper recycling platform, they founded Attero, an end-to-end electronic and electrical goods e-waste management company.

While Nitin is an alumnus of the New York University's Stern School of Business and Indian Institute of Technology-Delhi, Rohan is a chemical engineer.

| RE-CYCLING E-WASTE & EXTRACTING METALS |

|

Since 2009-10, when it started ground-level operations, Attero's revenue has risen from $1 million (Rs 4-5 crore) to $15 million (Rs 75 crore). It recorded break-even last year. The company has now caught eyeballs by tying up with the International Finance Corporation (IFC), the World Bank's private sector investment arm, for the Clean e-India initiative. Through this, it is roping in ragpickers and kabadiwallahs for proper disposal of electronic waste, training and making them part of its supply chain. The project is being rolled out across Delhi, Ahmedabad, Hyderabad and Mumbai.

"It was the success of Attero in e-waste management over a short span that attracted us in starting a similar initiative with them. Compared to its competitors, it has a technological edge and a pan-India identity. Moreover, its network reaches out to end-customers and the informal sector," says Subrata Burman of IFC. When Attero started operations, the number of companies in this sector was less than 10; this has increased to 90.

The company collects e-waste from about 500 cities - from original equipment manufacturing partners such as Samsung, Voltas, Wipro, Bosch, Siemens, HCL and Acer, as well as 500 bulk consumers - and moves about 450,000 kg of electronic assets. Last year alone, its e-commerce take-back platform, atterobay.com, collected 250,000 mobile phones.

The company, which has integrated forward and back-end collection channels, earns revenue by selling extracted metals to industrial and private consumers at commodity market prices. It also sells refurbished electronic items.

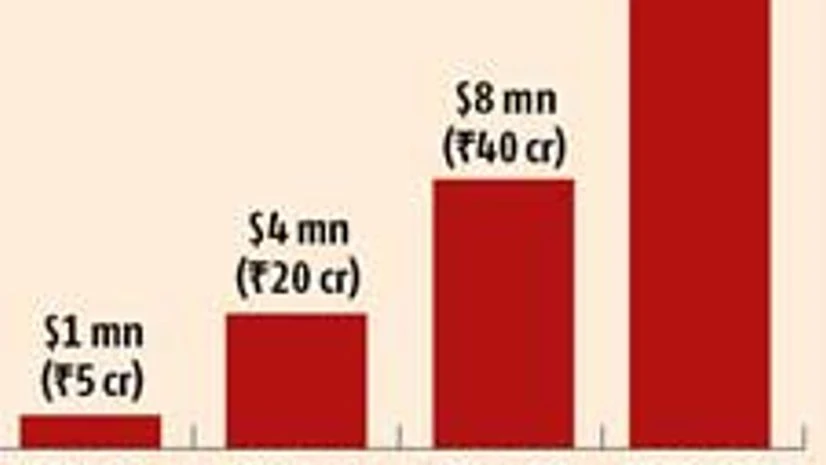

In 2011-12, Attero clocked revenue of $8 million (Rs 40 crore), in 2010-11 $4 million (Rs 20 crore) and in 2009-10 about $1 million (Rs 5 crore). The company says its online platform is gathering steam daily. Now, customers can type their model numbers and know the price in advance.

Attero's business model is based on a three-phased strategy. It collects 35 per cent of its tonnage from leftover manufacturing and faulty service electronics from original equipment manufacturers. Another 35 per cent comes from about 500 large companies such Wipro and Infosys, through replenished information technology equipment. The third category is everyday consumers, from whom its collects e-waste. The company has collection centres across 22 states. This is in contrast to most other companies in the sector, which are regionally focused.

The company's co-founder and chief executive, Nitin, attributes the success of its supply chain to the entire management team.

"It was based on a Power Point presentation that we secured series-A funding of $6.3 million from IndoUS Venture Partners and Draper Fisher Jurvetson during our inception in 2008. In 2008-09, our focus was on building the research & development and logistics team. In 2009-10, we started collecting end-life assets from large companies. The next year, we started working with original equipment manufacturers and the informal sector; now, we have reach in 500 cities. Our motto is reduce, re-use and re-cycle," says Nitin.

In 2010-11, the company recorded series-B funding of $8.3 million from IFC and Granite Hill Capital Ventures.

From its 100,000-sq-ft state-of-the-art facility in Roorkee, Uttarakhand, the company manages about 500 tonnes of e-waste.

"Here, through the process of electrorefining, we separate metals such as gold, silver and nickel from the other waste, later sold at market prices. It is this extraction and selling of precious metals that contributes to the majority of our revenue. In addition to this, we repair and sell re-usable goods. We are also planning to come up with a plant in Bangalore," Nitin adds.

The company also has an initiative with the National Association of Software and Services Companies, through which it supplies refurbished electronic items to schools and non-government organisations (NGOs).

For the Clean e-India initiative, the company has tied up with NGOs such as Guide Foundation for Development, Hyderabad, and International Centre for Entrepreneurship and Career Development, Ahmedabad. Through this and other campaigns, the company is ramping up its supply chain.

Says Pallav Sharma, an Attero coordinator: "When we go to collect waste directly through campaigns across housing societies in cities such as Delhi, the response from the middle class is overwhelming. We assure them complete data security, in addition to a similar price it might fetch in the local market, while assuring eco-friendly recycling."

Shot in the arm

In 2011, the company got a major boost when the government modified the producer responsibility policy.

A producer's responsibility for a product was extended to the post-consumer stage, including product disposal. Experts said this was the primary factor behind Attero tying up with original equipment manufacturers.

A Samsung official, in response to a query from Business Standard, said, "In India, electronic waste is increasing rapidly because of the growing adoption of electronic goods, as well as technological obsolescence. According to industry estimates, in India, e-waste from mobile phones alone is set to grow multiple times, which would push all stakeholders to support strong initiatives for recycling, according to e-waste regulations. Attero has an efficient logistics network and pan-India presence, which is helping Samsung to effectively manage its recycling processes."

Roadmap

The 17 per cent year-on-year growth of the $35-billion consumer market is driving growth for companies such as Attero. In 2009, the e-waste generated globally was about 40 million tonnes (mt); this has increased to 60 mt. India generates about one mt of e-waste a year and this is growing at about 30 per cent a year.

Nitin says about 85 per cent of the company's revenue comes from selling precious metals. The share of refurbished items sold would considerably increase in the coming years.

The challenge for Attero, as well as competitors such as Bangalore-based E-Parisaraa and Mumbai-based Eco Recycling, is in making this market more organised.

Nitin says: "Our advantage is the unique technology of extracting metals, which only a few companies in the world have. We want to record a turnover of $100 million before 2015-16 and make the most of the informal sector."

EXPERT TAKE

Compared to its competitors in India, one of the major advantages Attero has is its unique technology to extract metals out of e-waste. As someone who closely monitored the sector, I believe Attero still has a long way to grow. The current business model Attero follows has earned it a good market. With time, it needs to further leverage its online platform and strengthen informal sector tie-ups to cashi in on the $8-billion potential market. About 99 per cent of its waste intake is either recycled or refurbished. It is high time the company reached out to Tier-II cities and foreign markets. This sort of a business model would have takers abroad as well, as only five-six companies have similar technologies across the world. At the same time, there needs to be continued focus on research & development to improve further on efficiency of metal extraction. With government policies making extended producer responsibility for manufacturers compulsory, the challenge before companies such as Attero is to handle a larger market in a short time.

Gurdeep Singh, a sector expert, is a non-executive director at Blue Star and former director (human resources, corporate affairs and technology), Hindustan Unilever

)