State-owned Kudremukh Iron Ore Company Ltd (KIOCL), a 100 per cent export-oriented unit, is actively exploring ways to restart iron pellet exports after a gap of two years. The company is in talks with potential buyers in Iran and elsewhere in West Asia for exporting pellets, a top company official said. “Last week, Indian steel secretary held discussion in this regard with a business delegation from Iran and the deputy minister of mines, government of Iran, and offered to make use of the excess pelletisation capacity available at KIOCL’s Mangalore plant for pelletisation of iron ore fines from Iran,” said Malay Chatterjee, chairman-cum-managing director, KIOCL Ltd.

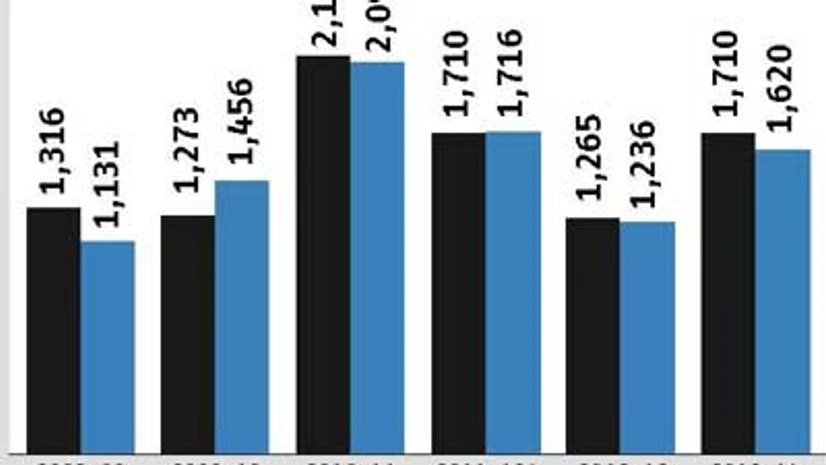

KIOCL operates a 3.5 million tonne per annum pellet plant at Mangalore with a captive berth at New Mangalore Port. It produced 1.7 million tonnes and sold 1.6 million tonnes of pellets in 2013-14. It has offered the remaining 50 per cent of the capacity to Iran for making pellets.

Subsequently, Chatterjee has interacted with Khalil Maleki Raee, the first secretary, economic section, Embassy of the Islamic Republic of Iran, and apprised him of the capabilities and facilities available at KIOCL’s pellet plant. KIOCL has expertise in mining and beneficiation of iron ore and is operating its plant for more 25 years.

“We have offered Iran that we can import iron ore from them and convert it into pellets with an Fe content of 64 per cent and export it back to their steel mills. We have a captive berth at Mangalore port with automatic loading and unloading facility, which can be used to import and export iron ore and pellets,” he said.

The company has offered to produce and export up to two million tonnes of pellets annually. “Iran will have to give us the processing cost,” Chatterjee told Business Standard.

“During my last visit to Iran along with KIOCL team to Esfahan Steel and Mobarekh Steel, it was indicated to us that there is an ample quantity of iron ore fines generated in Iran, which could be utilised for pelletisation at KIOCL’s Mangalore plant,” Chatterjee said in his communication to Embassy of Iran.

He said it would be economically viable to bring iron ore from Iran and convert it into pellets in India because the company is already sourcing ore from Kirandul and Bacheli sector in Chhattisgarh, which is about 2,200 km from Mangalore. Compared to this, the distance between Mangalore and Iran is much lesser, he said, adding it would also provide ore security in the form of blast furnace grade pellets for steel plants in Iran to be supplied by KIOCL.

“We want to start exports once again from this year, as we want to make use of idle capacity. Even though our margins will be very thin due to lower spot prices in the export market, we want to keep running our plant and reduce overhead costs,” Chatterjee said.

However, the KIOCL will continue to sell pellets in the domestic market as the prices have gone up in the recent past and the company is making a profit margin of Rs 500-800 per tonne, he said.

)