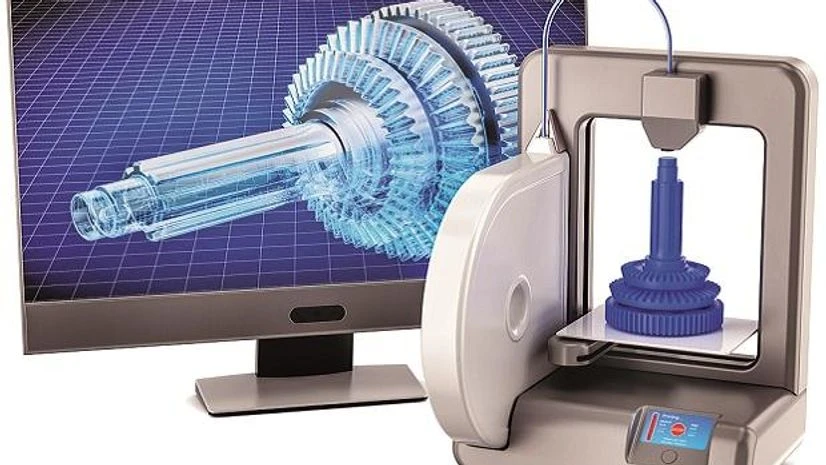

When the Indian Space Research Organisation (Isro) lobbed the GSAT-19 communication satellite into space using its Geosynchronous Satellite Launch Vehicle (GSLV) MK III last year, India became part of the prestigious ‘heavy-lift rocket club’. But the mission achieved another quiet victory: it used a 3D-printed component on the satellite, proving that India is now able to successfully employ additive manufacturing, or 3D printing technology, to produce parts that can withstand the extreme conditions of space.

Manufactured by Wipro 3D (a division of Wipro Infrastructure Engineering) in collaboration with Isro, the 3D-printed feed cluster antenna was part of the communication system of

)