Cotton yarn spinning mills are mulling a response to the fall in Chinese export demand. A serious matter, since mills had significantly raised their capacities in the past three years in response to rising demand from that country, for both cotton and yarn.

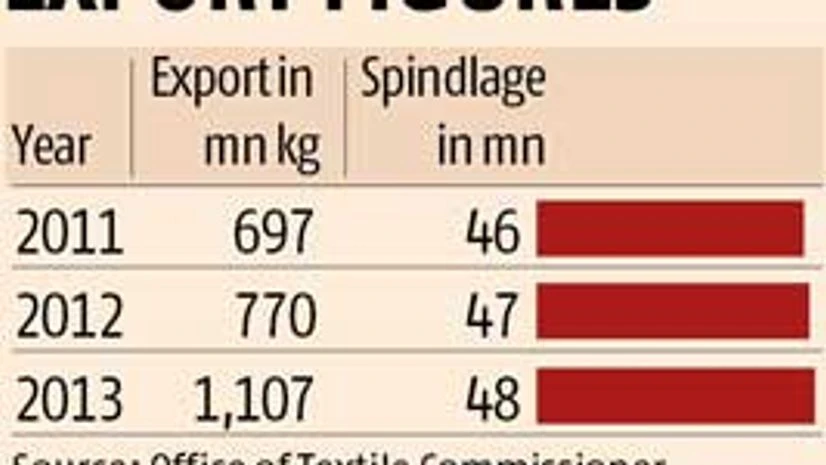

Mills added a combined 500,000 spindles in the past five years, anticipating a consistently high demand from China. There certainly was a big jump in 2013 over 2012, from 77 million kg of yarn export to 1,107 mn kg.

However, the Chinese government has cut the reserve price for sale of cotton in the domestic market; it also plans to release more of cotton from its reserves than before. The Chinese currency, the yuan, is also depreciating, making imports costlier.

Also, says a report from the International Cotton Advisory Committee, polyester is becoming cost-competitive in China as compared to cotton.

Kamal Oswal, managing director of Ludhiana-based Nahar Spinning Mills, says exports to China have become sluggish, with demand down 30-40 per cent. His company exports yarn and fibre to China. Slack demand from China, he said, had to be offset by adding new export destinations.

One hope for Indian exporters is the fact that Chinese garment units are considering moving to other places. Hardyal Singh Cheema, managing director of Cheema Spintex, says: “High labour cost in China, coupled with the compulsion of using Chinese cotton stock (less competitive than imported cotton for these units) might drive them out of China. Vietnam and Cambodia are more cost-competitive for garment manufacturers, so we are mulling diversifying our export to these countries.”

Cheema says China is likely to cut on cotton sowing in the coming season, to increase the area under staple crops. This might help revive cotton imports from there. Indian mills, nevertheless, will have to foray into new markets to reduce dependence on China. D K Nair, secretary-general of the Confederation of Indian Textile Industry, said an appreciating rupee and depreciating yuan in recent times made Indian imports more expensive for China. So, they’ve started releasing their own cotton stocks; a short-term measure, he added. Owing to China’s high manufacturing cost, making of yarn and fabric would be unviable in the long run.

)