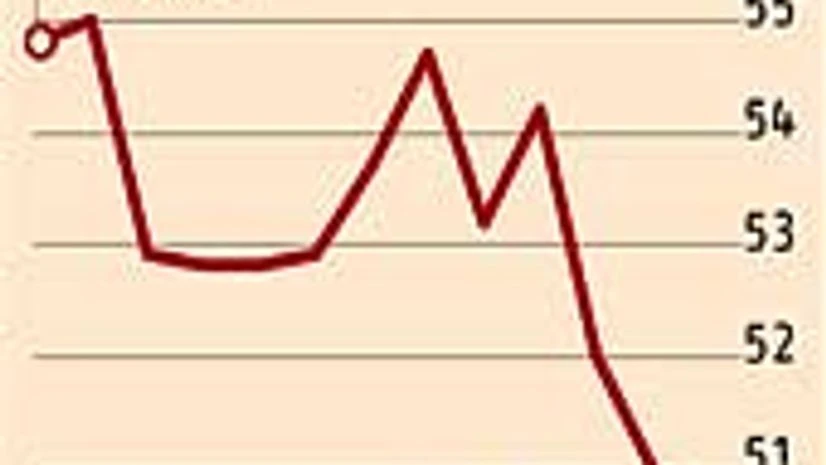

As if slowing orders were not bad enough, now power shortage is preventing completion of whatever few orders that Indian factories are sitting on. India's manufacturing sector is stagnating, if HSBC Purchasing Manager's Index (PMI) reading for the month of May is anything to go by. HSBC's PMI reading for the last month has fallen from 51.0 in April to 50.1 in May. The slowdown continues to deepen even on a sequential basis. If one compares the March quarter, PMI averaged at 53.1 per, which has fallen to 50.6 in April and May period. Softening PMI reading between April and May dashes hopes of a recovery, says Sonal Varma, chief economist of Nomura.

So far, PMI has been weakening, but in May, it hit its lowest since March 2009, which is "reflective of weaker gains in incoming new work and persistent power outages". While falling demand has resulted in soft factory output, power outages are affecting the completion of existing orders as well. The delivery schedules of factories have gotten extended, due to power shortage and labour issues.

For the past couple of years, the sector's output has been hit due to poor availability of land and raw materials. Now even power is becoming scarce, affecting completion of orders. Power analysts say states like Tamil Nadu and Maharashtra are facing power outages for long hours. Leif Eskesen, chief economist for Asia and ASEAN at HSBC Global Research, says it is evident that the economy remains supply constrained as frequent power failures prevent businesses from meeting orders despite the fact that these are now growing at a slower clip. The bright spot is that export orders are picking up despite weak global sentiment. HSBC says growth in export business has been solid and the fastest since January 2013. Even though export orders have seen a pick up, execution of these orders is becoming an issue due to operational challenges.

More From This Section

However, weak factory data suggests that things are not picking up and that a revival is some way off. Weak domestic demand and supply constraints imply that the broader issues affecting industry are not being resolved. The overall imprint suggests that demand is not reviving and with reforms process coming to a standstill in recent times, a revival is not imminent even in the new fiscal. Analysts believe that India is frittering away the opportunity to capture a share of global manufacturing. On the other hand, global manufacturing is shifting from outsourcing due to technology (less dependence on labor for scale-up), resources (shale gas in the US) and political attitudes (rising unemployment), says Kotak Institutional Equities. A policy push is needed to reverse this slide in manufacturing.

)